Standard Information IEC 61000-4-2 Ed.3 Standard Overview

NoiseKen1. General

The international immunity test standard which applies to electronic equipment against ESD generated directly from a human body or near metal objects in condition chemical fibers carpets or clothings are used in low humidity relatively. This standard assumes cases when charged human body discharges to electronic equipment and testing with the circuit to simulate current waveform generated in such conditions.

2. Test Levels

■ Test level values for ESD

The test levels for ESD are shown below. Air discharge is tested at all test levels up to the specified test level, and contact discharge and indirect discharge tests are tested at the specified test level.

| Level | Test voltage | |

| Contact Discharge | Air discharge | |

| 1 | 2kV | 2kV |

| 2 | 4kV | 4kV |

| 3 | 6kV | 8kV |

| 4 | 8kV | 15kV |

3. Verification of test generators and waveforms

■ Generator specification

The generator must satisfy following specification.

| Parameter | Values |

| Output voltage | Contact discharge: 2kV to 8kV Air discharge: 2kV to 15kV |

| Output voltage tolerance | ±5% |

| Output voltage polarity | Positive and negative |

| Holding time | 5 seconds or more |

| Discharge Mode | single-shot discharge |

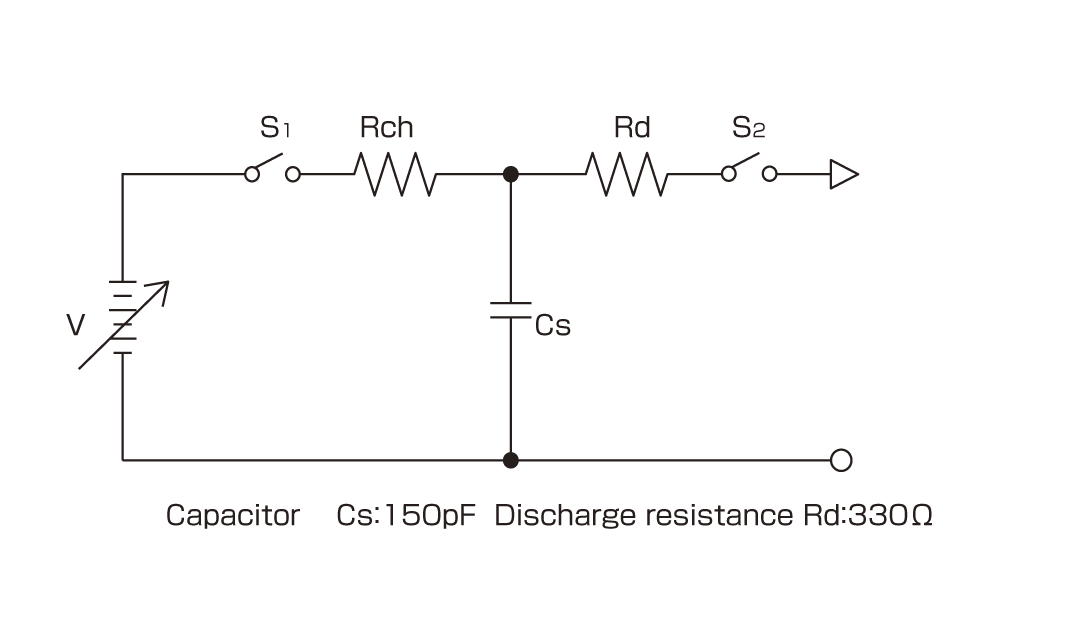

Simplified diagram of the ESD generator

■ Generator characteristics

The characteristics in the following table must be verified in order to compare the tests results among different generators.

| Level | Indicated voltage | 1st peak current I p1 (±15%) | Rise time t r (±25%) | Second peak current I p2 (-20%/+40%)* | Current value at 30ns I 30 (±30%) | Current value at 60ns I 60 (±30%) | |

| Contact Discharge | Air discharge | ||||||

| 1 | 1 | 2 kV | 7.5 A | 0.8 ns | 4.5 A | 4.0 A | 2.0 A |

| 2 | 2 | 4 kV | 15.0 A | 0.8 ns | 9.0 A | 8.0 A | 4.0 A |

| 3 | — | 6 kV | 22.5 A | 0.8 ns | 13.5 A | 12.0 A | 6.0 A |

| 4 | 3 | 8 kV | 30.0 A | 0.8 ns | 18.0 A | 16.0 A | 8.0 A |

| — | 4 | 15 kV | 56.3 A | 0.8 ns | 33.8 A | 30.0 A | 15.0 A |

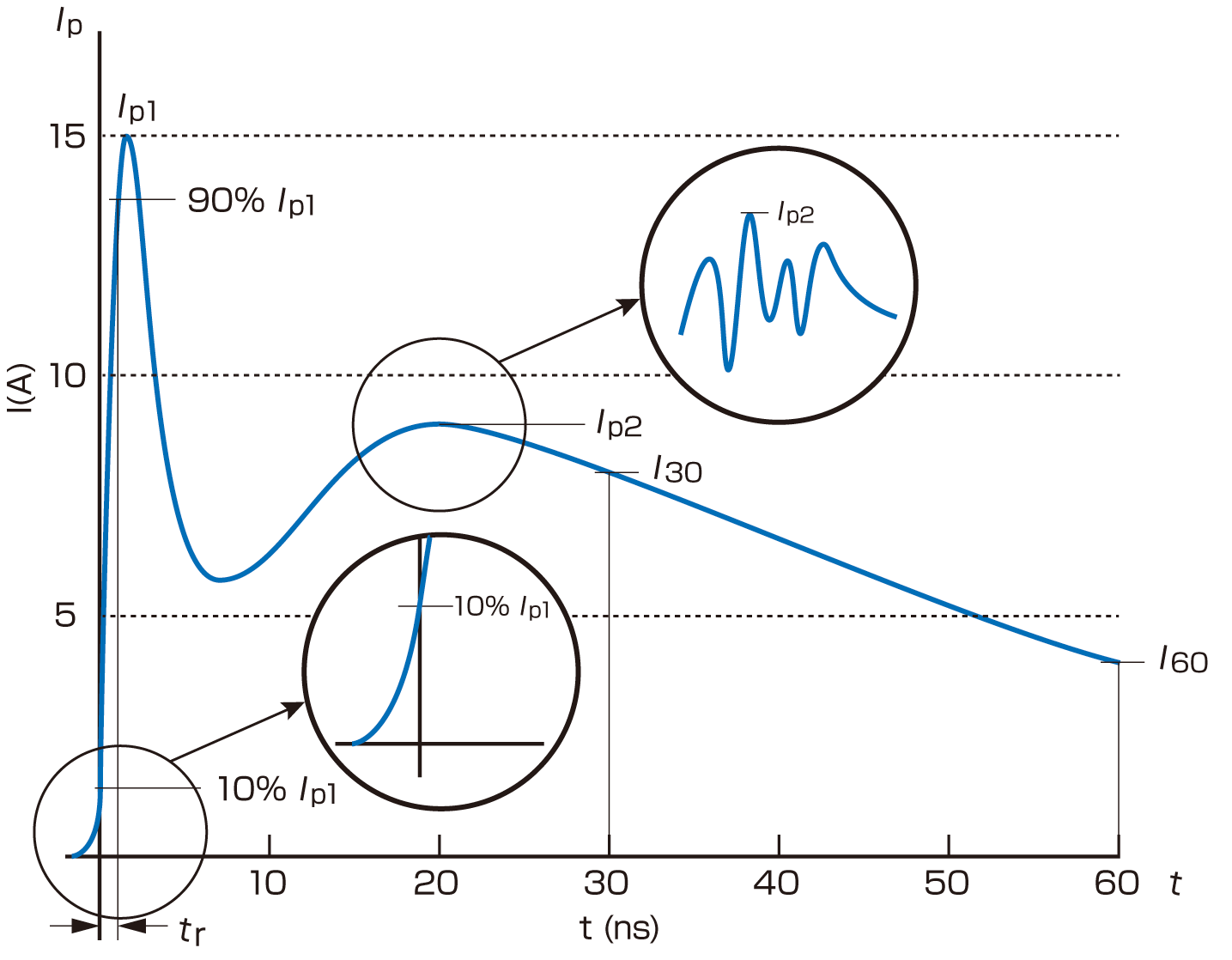

Discharge current waveform and its characteristics

* I p2 is the maximum value in the 10ns to 40ns interval

Discharge current waveform of contact discharge at 4kV

Contact discharge and air discharge are shown in the level column of the discharge current waveform parameter, and the discharge current waveform regulations apply to contact discharge as well as air discharge.

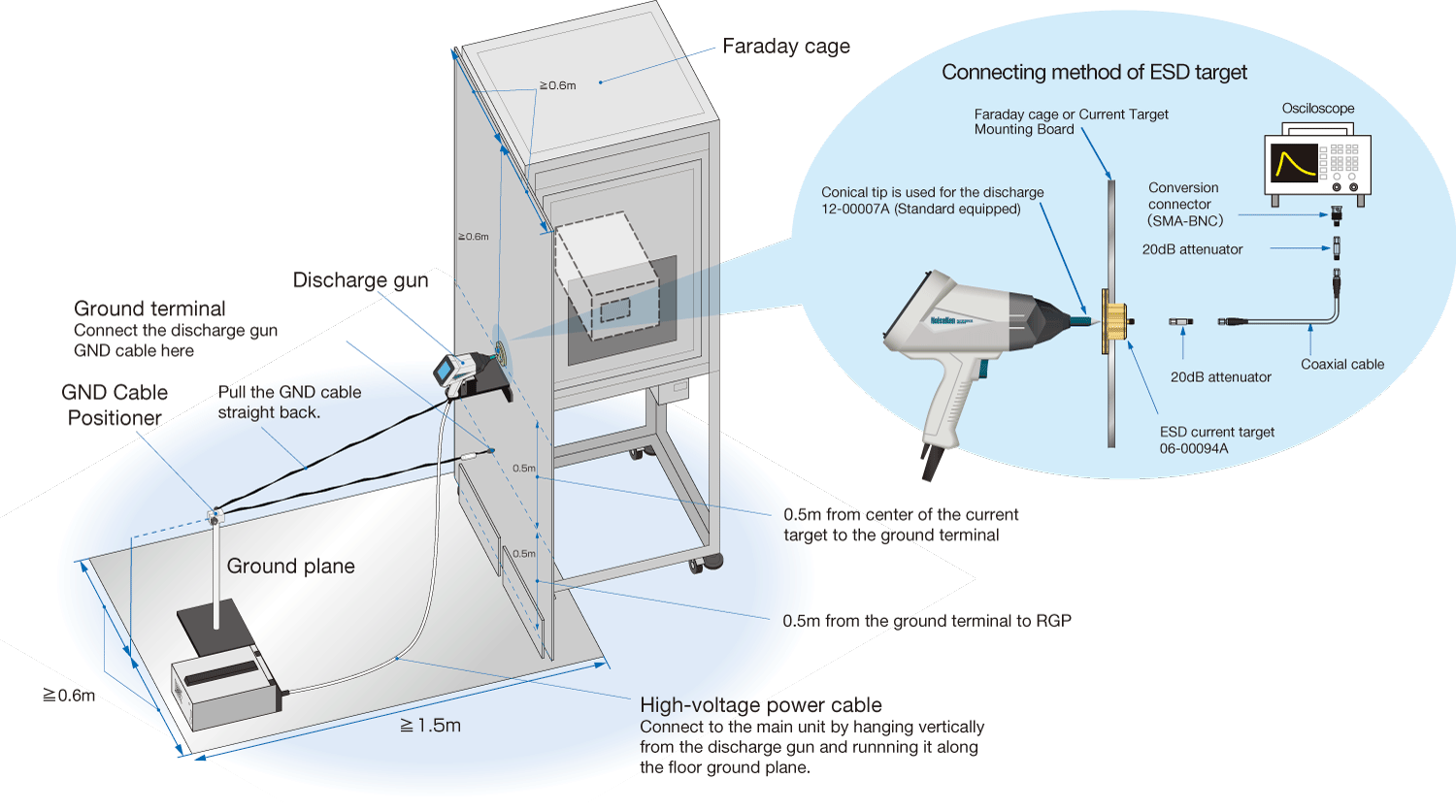

■ Waveform verification of ESD Generator

There are no changes to the regulations for current targets and oscilloscope bandwidths, etc. However, the setup for discharge current calibration has been changed, with the height of the current target fixed at 1 m and a floor ground plane required. To improve reproducibility, the high-voltage cable of the electrostatic tester should hang vertically from the discharge gun and be connected to the body of the tester along the floor ground plane, and the main unit of the electrostatic tester should also be installed on the ground plane.

* Insertion use of approx. 20 dB attenuator for protecting the measurement equipment is recommended, although it is not specified in the IEC Standard.

4. Test Setup

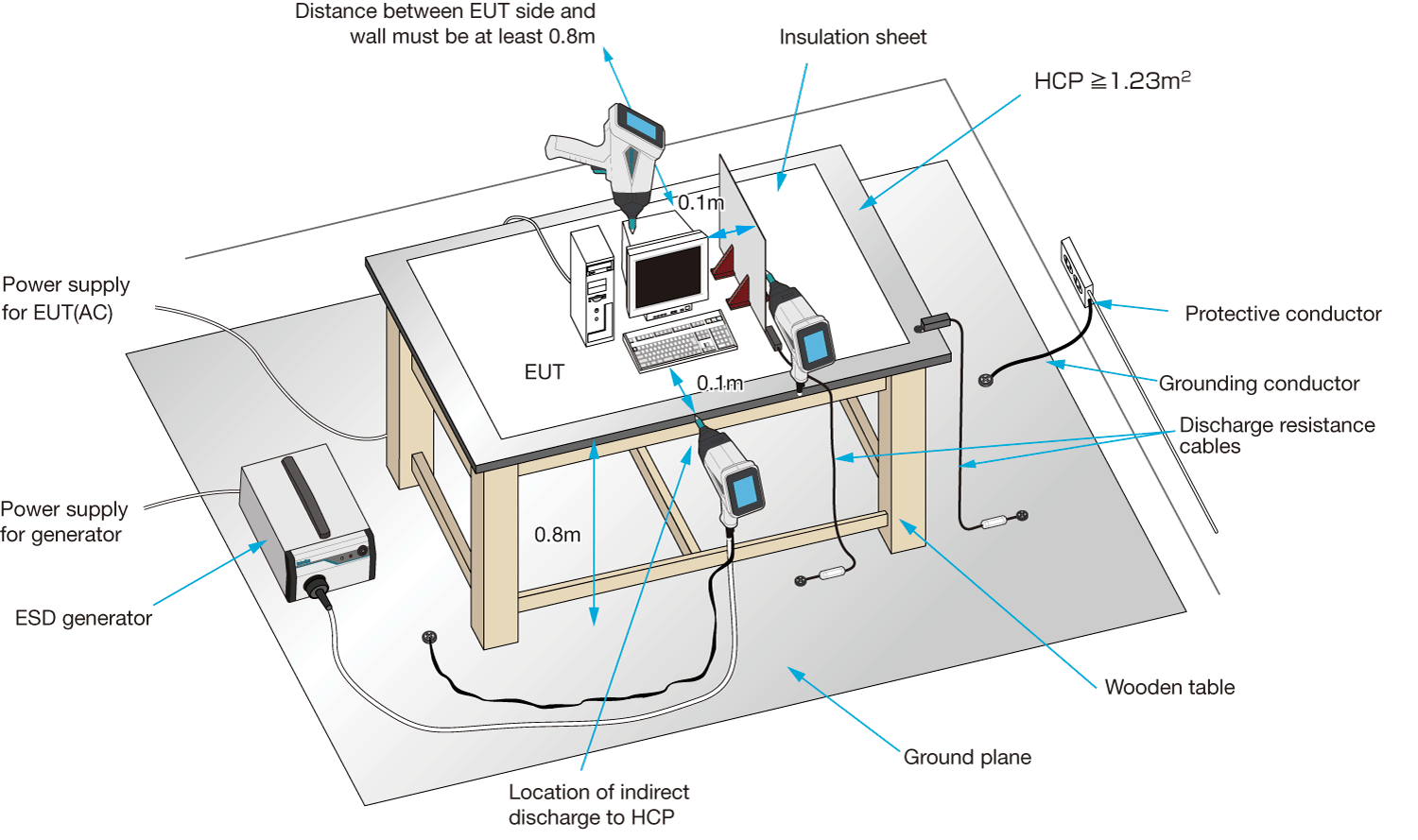

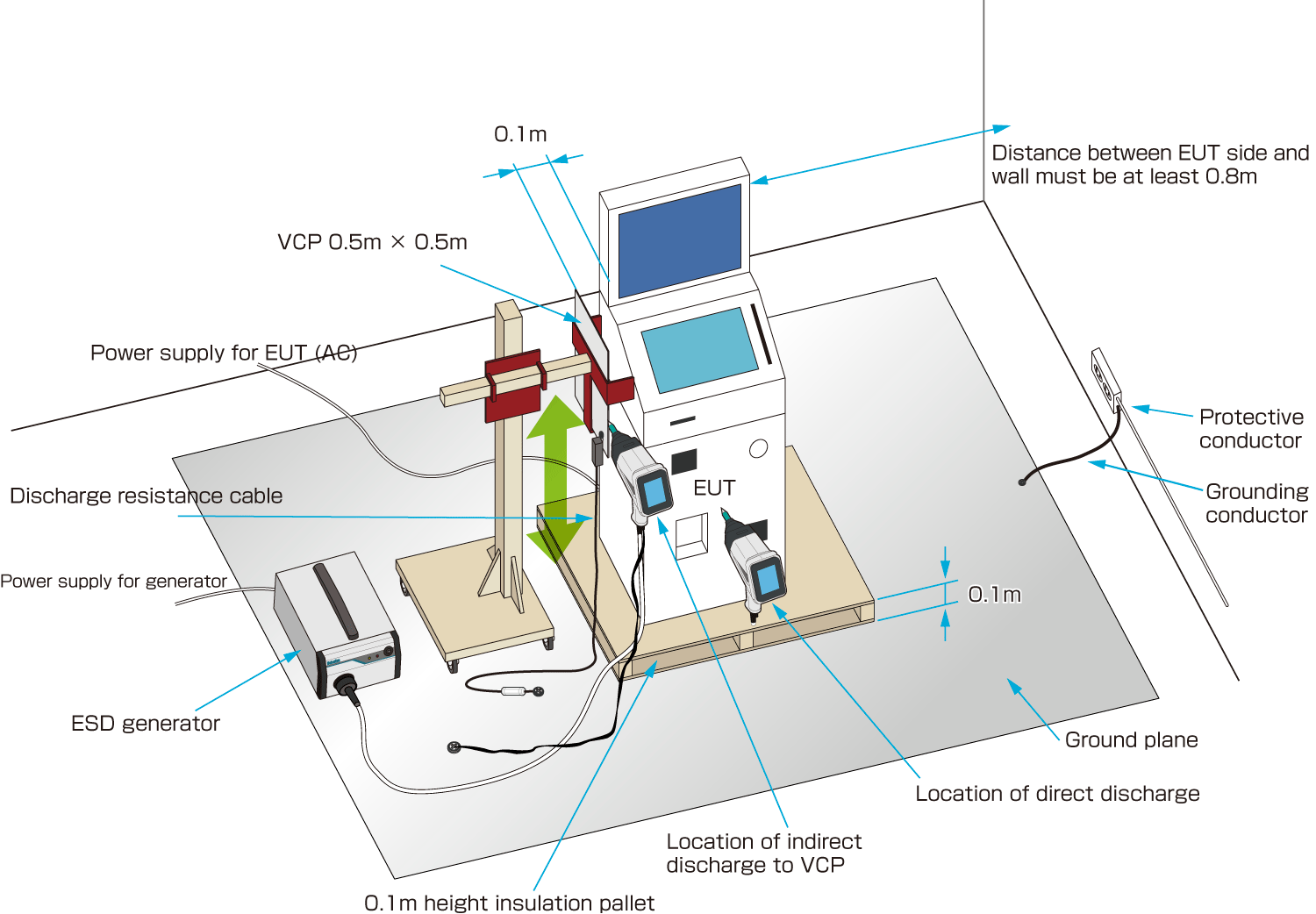

■ Example test setup for table-top equipment

【Direct discharge test】

The direct discharge test is a test in which the EUT is directly discharged to verify the effect to the device. A wooden table 0.8 m high is placed on the ground plane and a horizontal coupling plane is placed on top of it. The horizontal coupling plane is connected to the ground plane with a discharge resistor cable. Place an insulating sheet between the horizontal coupling plane and the device.

【Indirect discharge test】

The indirect discharge test is a test in which the horizontal and vertical coupling planes are discharged to verify the effect to the EUT . In addition to the test environment for direct discharge testing, a vertical coupling plane ( 0.5 m x 0.5 m ) is used. The vertical coupling plane is also connected to the ground plane with a discharge resistor cable.

The cables of the equipment are floated off the horizontal coupling plane with 0.5 mm insulation sheet.

<Basic test setup>

(1) The distance between the 470 kΩ resistance of the discharge resistance cable and the terminals shall be within 0.1 m at both ends.

(2) The total length of the discharge resistance cable to the horizontal coupling plane shall not exceed 1.5 m.

(3) The total length of the discharge resistance cable to the vertical coupling plane shall not exceed 3 m.

(4) Auxiliary equipment can be installed inside or outside the test environment, and the connection cables of auxiliary equipment can be decoupled.

(5) Horizontal coupling plane regulations were changed from dimensional rules to area rules. Not only rectangular shape, but also square, round and other shapes are acceptable.

For table-top equipment

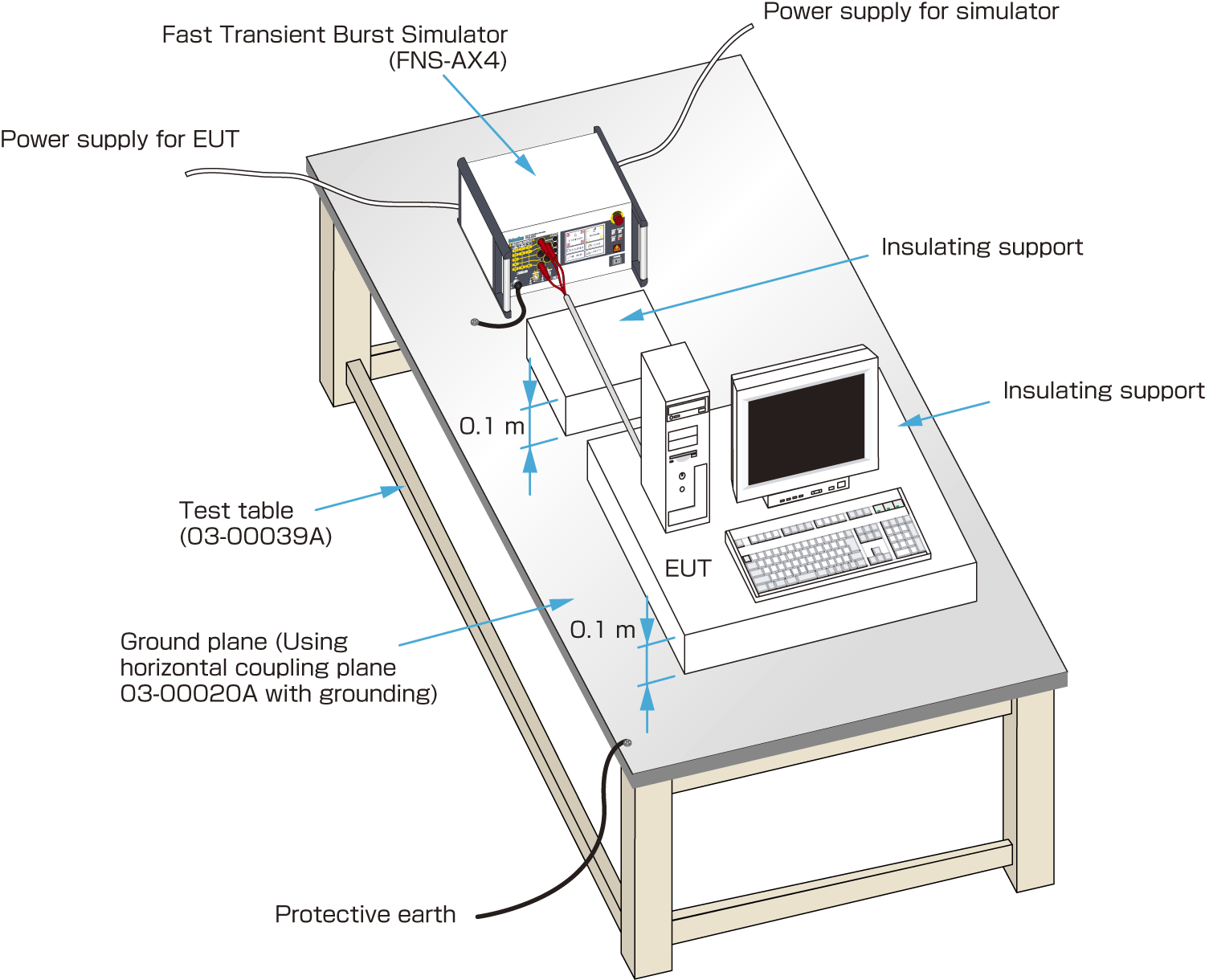

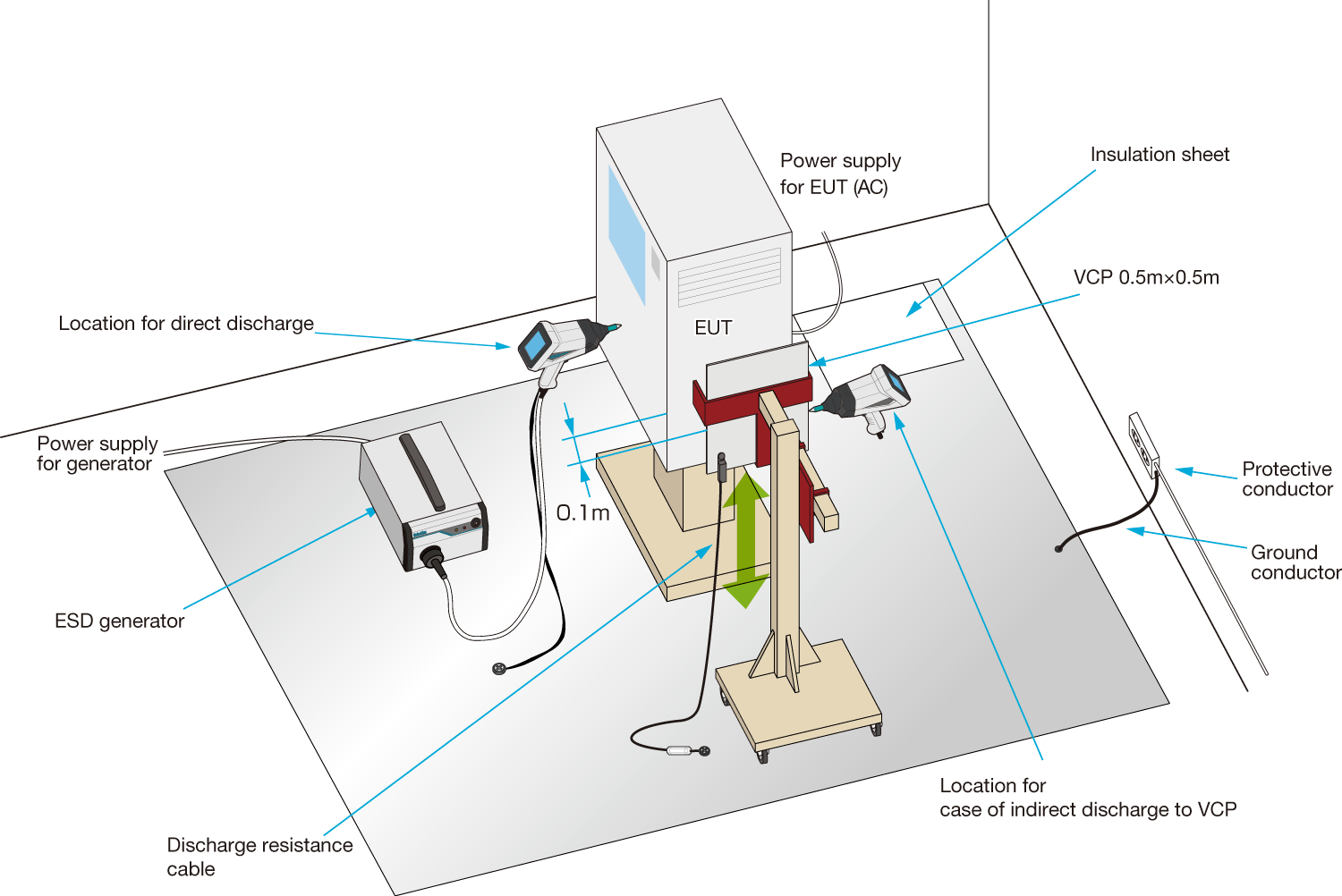

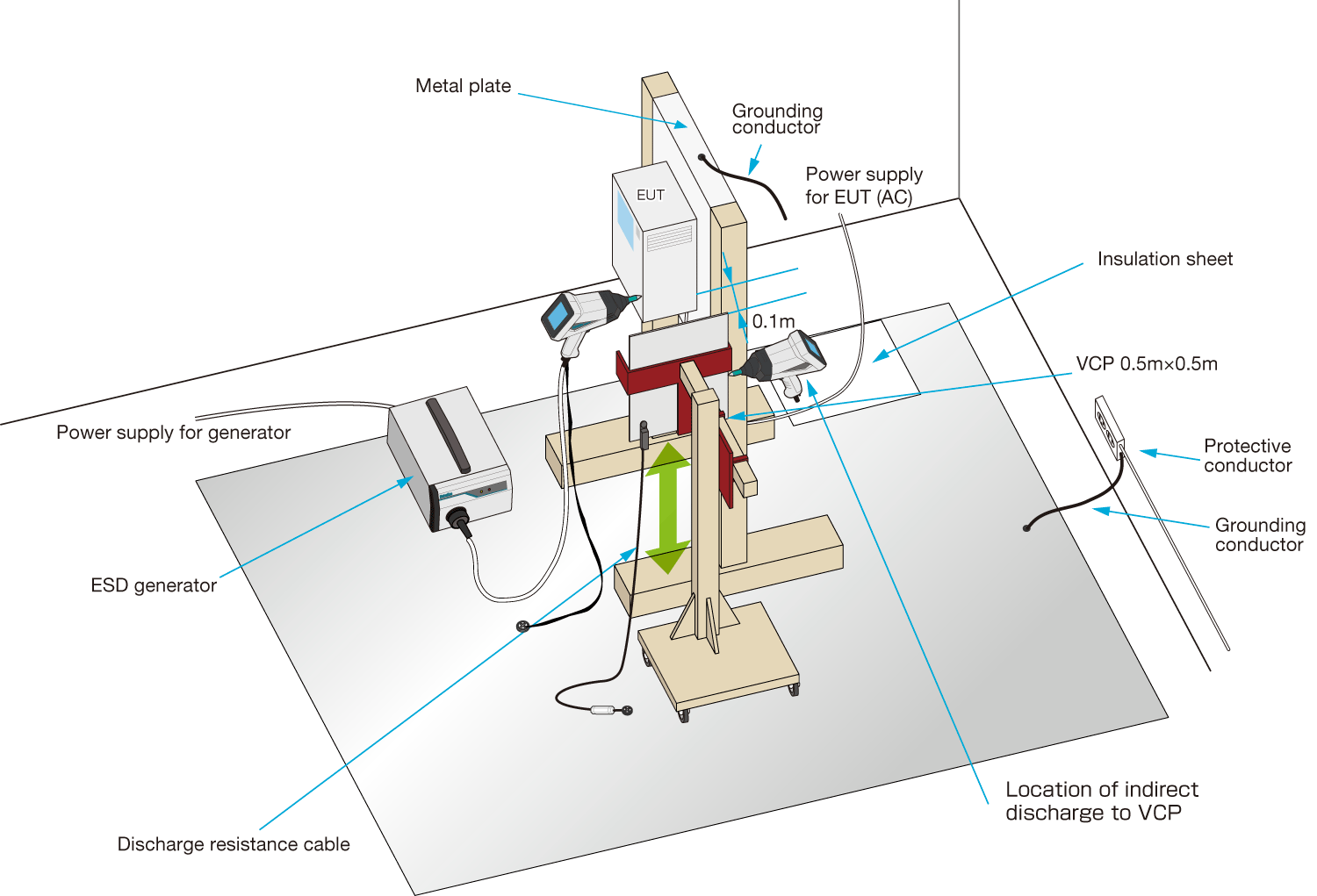

■ Example test setup for floor-standing equipment

【Direct discharge test】

Place an insulating support 0.1 m high on the ground plane and place the EUT on top of it.

【Indirect discharge test】

A test to verify the effect to the EUT by application of the discharge to a vertical coupling plane. The vertical coupling plane is connected to the ground plane with a discharge resistor cable.

Equipment cables are floated off the ground plane with 0.5 mm insulation sheet.

<Basic test setup>

(1) The distance between the 470 kΩ resistance of the discharge resistance cable and the terminals shall be within 0.1 m at both ends.

(2) The total length of the discharge resistance cable to the vertical coupling plane shall not exceed 3 m.

(3) Auxiliary equipment can be installed inside or outside the test environment, and the connection cables of auxiliary equipment can be decoupled.

For floor-standing equipment

■ Test Setup for table-top and floor-standing equipment *For Ungrounded Equipment

There are no changes to the basic test setup for testing ungrounded table-top and floor-standing devices, but ungrounded devices are defined as Class II devices as defined in IEC 62368-1.

If the test results differ due to the connection of the discharge resistance cable to the EUT, disconnect the discharge resistance cable, apply ESD, then reconnect the cable and perform static elimination. The distance to the 470 kΩ resistance of the discharge resistance cable is within 0.1 m.

■ Test setup for wall-mounted equipment

[For non-conductive surfaces] Place a 0.8 m high non-conductive support on top of the ground plane and place the device on top of it for testing.

[For conductive surfaces] The test is performed by mounting the device on a grounded metal wall with a distance of 0.8 m from the ground plane to the bottom of the device.

Other regulations are not significantly different from the test for floor-standing equipment.

If the mounting surface is a non-conductive wall

If the mounting surface is a conductive wall

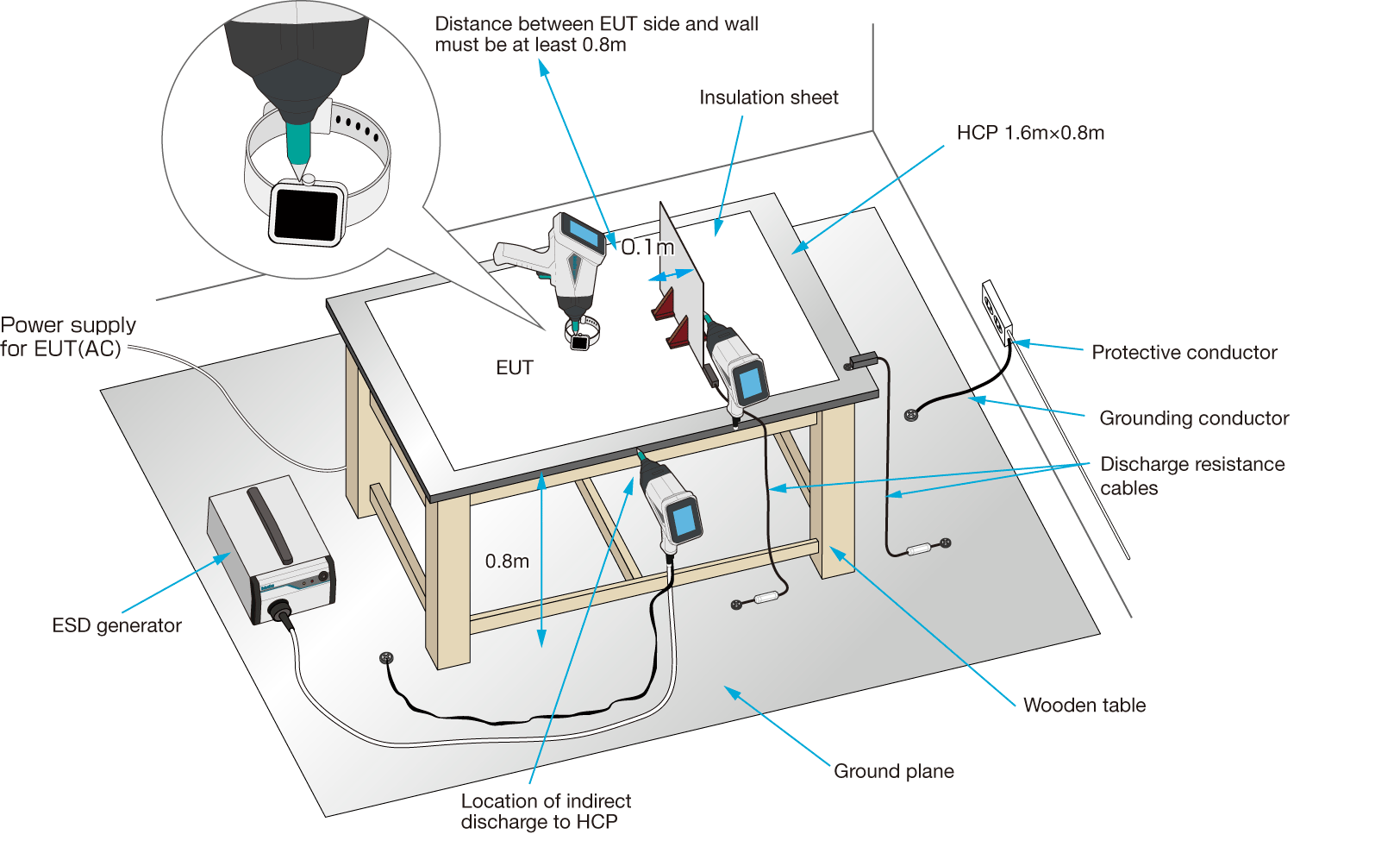

■ Test Setup for Wearable Devices

Test is conducted at the test setup of table-top equipment for ungrounded devices.

For additional experimental testing, the recommended charging capacitor and discharge resistor are 200 pF and 50 Ω, respectively, to reproduce the most severe discharge current conditions from a wearable device worn on the waist.

5. Test procedure

■ Climatic and Other Environmental Conditions

It is necessary to let the equipment brought in from different climatic conditions to fully adjust to testing environment before performing the test. Also, in order to stabilize the discharging condition, it is necessary to control the climatic conditions in the test room. Fulfillment of the conditions listed in following table must be required to perform testing in conformance with IEC61000-4-2.

| Climatic conditions | |

| Parameter | official regulations |

| Ambient temperature | 15℃~35℃ |

| Relative humidity | 30%~60% |

| Atmospheric pressure | 86 kPa (860 mbar) to 106 kPa (1060 mbar) * Values published by a meteorological observatory may be used. |

| Tests may be performed at relative humidity of 30% or less, but no further action is required if the EUT meets the specified performance criteria within these conditions, otherwise the test shall be performed within the relative humidity range described above. | |

| The electromagnetic conditions shall be such that the correct operation of the EUT is guaranteed in order not to affect the test results. | |

■ Test Procedure

Direct discharge test: contact discharge (discharge at 1 second intervals) and air discharge (approach the EUT as quickly as possible).

Indirect discharge test: Applied to vertical and horizontal coupling planes.

Indirect discharge testing to the horizontal coupling plane targets the surface on which the EUT is normally installed, and testing of metal housings, especially EUTs with PE connections, is no longer necessary. Indirect discharge testing using a vertical coupling plane is performed on an accessible surface of the EUT.

The number of discharges is at least 10 discharges at 1 second intervals, both polarities.

A preliminary test can be performed by discharging 20 times per second or more repeatedly in order to determine the discharge points.

6. Escalation strategy

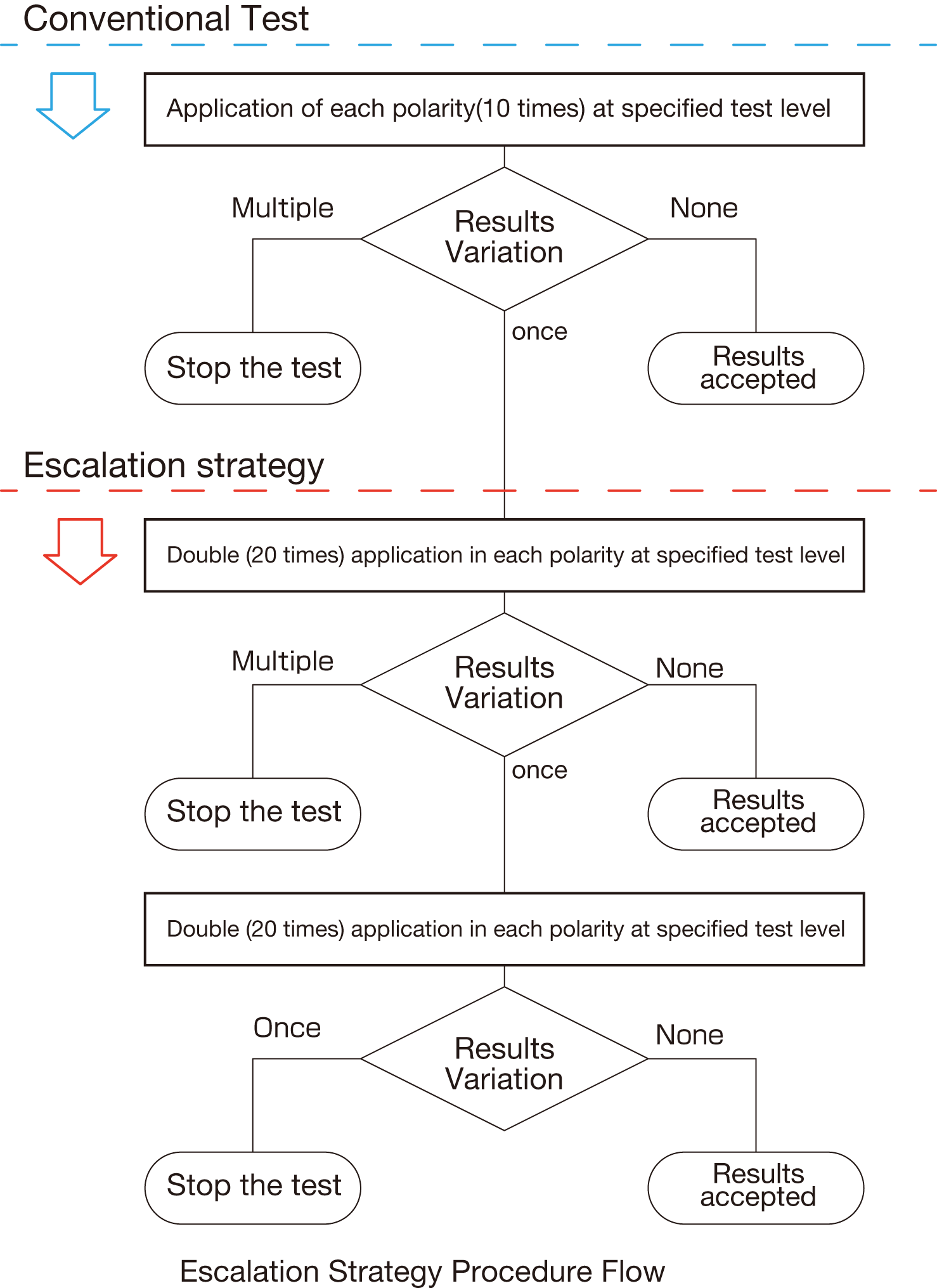

If there are variations in the performance of the equipment during a direct discharge and it cannot be determined if the variations are due to the application of the discharge, an escalation strategy is applied.

If the device experiences a variation in performance during the application of a discharge and it is impossible to determine whether the variation is due to the application of the discharge, use the flowchart on the left as a guide. (Regulation)

Note: Not applicable if the application of the discharge allows the device to consistently perform the same operation and the test result can be determined.

If one variation occurs during 10 applications in the actual test, the result is accepted if 20 applications are made again and no variation occurs.

If one more variation occurs during the additional test, it will be accepted if no malfunction occurs after another 20 applications, and if multiple variations occur, it will be inapplicable.

7. Evaluation of Test Results and Test Report

■Test Results (Reference)

Test results are classified according to EUT specifications and operating conditions as follows:

Performance Criterion A: Normal operation within specifications

Performance Criterion B: Temporary degradation of function or performance that can self-recover.

Performance Criterion C: Temporary degradation of functionality or performance requiring operator intervention or system reboot.

■Test report

The following items are newly stipulated

〇 Test level

〇 The length of the discharge return cable

〇 Performance criteria specified in the generic, product or product-family standard

〇 Test setup

〇 Diagram or photograph indicating the discharge points

〇 Number of discharges per discharge point

〇 HCP dimensions and shape, if used

〇 Escalation strategy, if used

Note: This test method and connection method are excerpted from the IEC 61000-4-2 Ed.3 standard, and an example is shown using our product. Please refer to the original Standard for detailed test methods.